Project Gallery

GNB Global has worked with an unexpectedly diverse assortment of industries over the years. We expected to work closely with the gas, oil, mining, sand, and salt industries. Little did we suspect as we started this that we would be creating a monk seal habitat in Hawaii, the 2013 Canadian Football League Grey Cup event facility, a trapeze training facility, or a library at the University of North Texas.

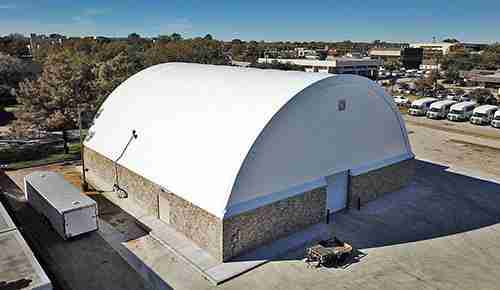

View a sample of our work in the project gallery below. Each thumbnail represents a series of pictures for each project.

Gerdau Steel

Dow Storage Buildings

Dallas Circus Center Building

Rainy River Mine

New Gold Mining Building

Pembina Pipeline Building

Texas Oncor Service Building

Okanagan Wealth Advisors Pickleball Complex

Rocky Comfort Salt Storage Building

M.G. Carter, Sr. Softball Complex

Lanier Material Sales Landscaping Storage

Columbia Canine Sports Center

Customs Inspection Building

Mission Arlington Warehouse

Dallas United Crew Building

Minnesota Public Works Facility

Robins Air Force Base C-17 Hangar

Natural Soil Products Compost Building

Prodesa Biomass Building

Naval Air Station Corpus Christi

GMCO Salt Storage Building

Go For It Sports Facility

Ship Rail-Mounted Building

Ash Grove Cement

Rose Acres Composting Building

Garland Salt Storage Building

Arizona Composting Facility

Columbus Air Force Base Sunshades

Tyndall Air Force Base Hangar Building

Monsanto Mining Storage Building

Cheshire Community Pool Building

Hilltop Ranch Fumigation Buildings

Top Gro Agro Fertilizer Building

Beaumont Salt Storage Building

Shell Albian Sands